Software Products MC2000

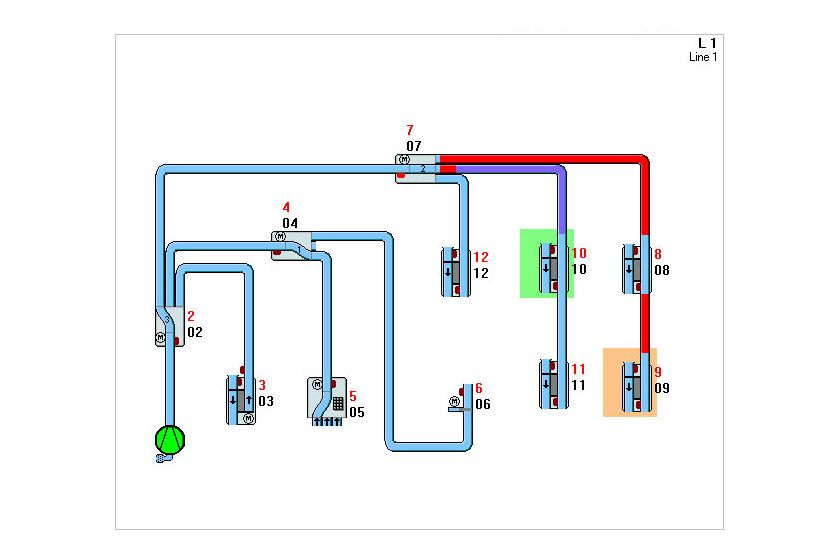

Visualization and Configuration

The entire pneumatic tube system is displayed via a graphic visualization system.

Systemcomponents could be configured and changed graphically. All information on past and current transports is shown.

Fire Alarm Contact

The purpose of a fire protection contact is to alert thepneumatic tube system in the event of fire. This capabilityis used to prevent fans from transporting smoke fromthe source of the fire to other rooms. The activation of afire protection contact causes the entire system or partsof it to shut down. This significantly improves the safetyof employees and personnel in the event

of fire

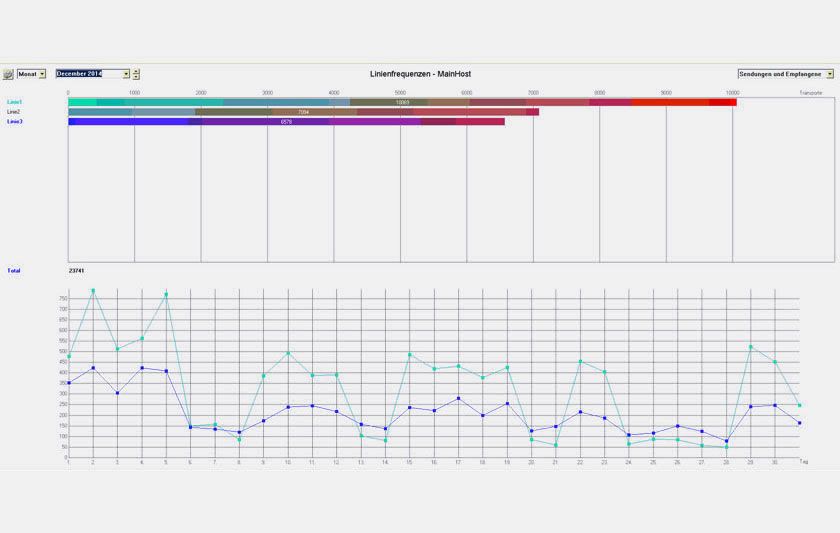

Historie & Evaluation

An overview of all transport statistics are shown both via graphics and in a table-format. Ranges of statistics to be shown can be defined individually: daily, monthly, annually or for special days, This feature gives you a glance at how the pneumatic tube system eases your normal work day.

Identificationssystem

The identification systems ensure that only authorisedpersonnel can send and receive capsules. Furthermore,there are several security levels and these can bedifferent e.g. for physicians and nurses.

An appropriate record is created each time a basket is opened.

An appropriate record is created each time a basket is opened.

Remote Maintenance

Your Hanazeder service team will assist you in an emergency within the shortest time possible via remote access.

Speed Adjustment

Different goods require different transport speeds.n.

The default speed is approximately 6 m/s, which has to be slowed for blood samples to about 3 m/s to avoid distorting laboratory results. Modern fan-speed controls allow for a dynamic adjustment of transport speeds.

The default speed is approximately 6 m/s, which has to be slowed for blood samples to about 3 m/s to avoid distorting laboratory results. Modern fan-speed controls allow for a dynamic adjustment of transport speeds.

E-mail, SMS or Phone Notification

A notification can be sent to the user when a capsule has reached its destination. This message can be sent via email, SMS or over the phone.

In the event of a disruption, the responsible technician is notified about the problem via email or phone. This message may also include information regarding the location and cause of the disruption.

PipeIDS- Browserbased Carrier Tracking

Carrier tracking is available to every pneumatic tubeuser. The system operates via a web interface and doesnot require the rollout or installation of specialised software;it can be used immediately from every device onthe network.