Industry

Incoming Samples

Raw materials delivered are tested in the laboratory in order to ensure quality.

By transporting the incoming samples with the pneumatic tube system, the idle time of trucks or trains is considerably shortened and thus costs incurred enormously reduced.

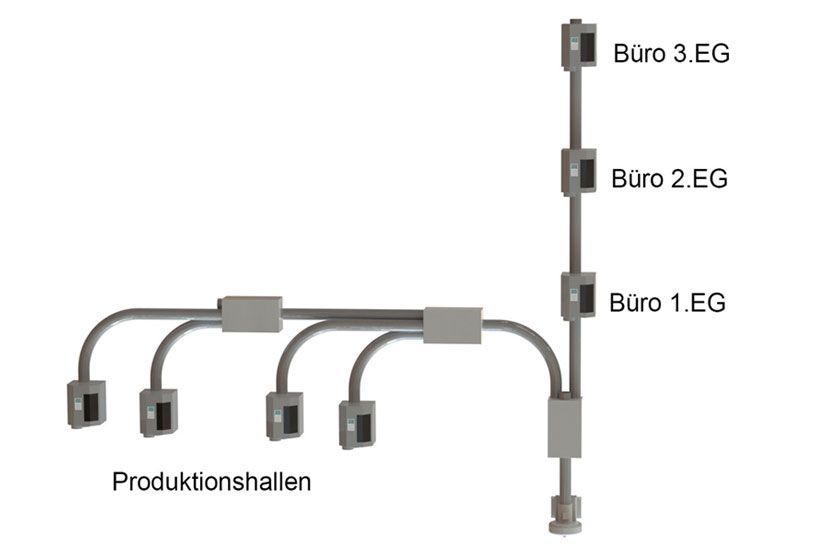

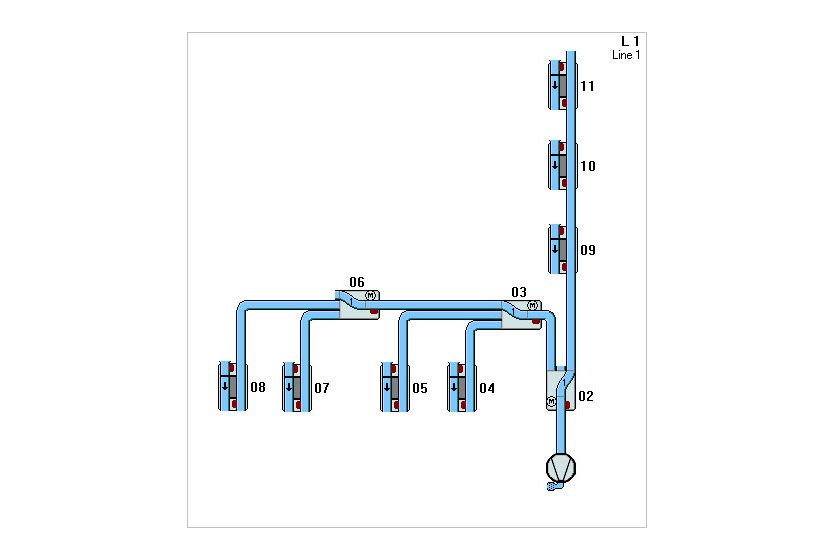

Production

The ongoing quality monitoring of goods produced presents logistical challenges for many companies.

System solutions adapted to each customer makes our pneumatic tube system highly efficient and the cheapest transport option for quality assurance.

Logistics

Documents and original files often have to be carried through huge buildings and work premises.

The costs for manual transportation of these goods are often overlooked.

Our pneumatic tube systems make it possible to transport these goods quickly and spontaneously.

Automation

Conveyor belt logistics, production lines and commissioning.

Modern pneumatic tube conveyors help optimize production processes and control the flow of material